PE water supply pipe product introduction

product introduction

PE water supply pipes and fittings are produced with PE100 or PE80 as raw materials. The specifications, size and performance meet the requirements of GBT13663-2018 and GB/T13663.2-2018 standards. The sanitary performance meets the GB/T 17219 standard and the relevant health and safety evaluation regulations of the Ministry of Health of the People's Republic of China. PE water supply pipes have the characteristics of good flexibility, strong corrosion resistance, light weight and excellent impact resistance. Pipe and pipe fittings can be connected by hot melt socket, hot melt butt and electric fusion, so that the pipes and pipe fittings are fused into one. The system is safe and reliable, and the construction cost is low. It develops rapidly in engineering applications.

product features

1. Long service life. Under normal conditions, the minimum life is 50 years

2. Good hygiene. PE pipe is non-toxic, does not contain heavy metal additives, does not scale, and does not breed bacteria. It solves the problem of secondary pollution of drinking water. In line with GB/T17219 safety evaluation standards and relevant health and safety evaluation regulations of the Ministry of Health.

3. It can resist corrosion of various chemical media; no electrochemical corrosion.

4. The inner wall is smooth, the friction coefficient is extremely low, the medium's passing ability is correspondingly improved and it has excellent wear resistance.

5. Good flexibility, high impact strength, strong shock resistance, distortion

6. Light weight, convenient transportation and installation.

7. Unique electric fusion connection and hot melt docking, hot melt socket connection technology makes the interface strength higher than the pipe body, ensuring the safety and reliability of the interface

8. The welding process is simple, the construction is convenient, and the comprehensive cost of the project is low.

product application range:

municipal water supply system, building water supply system and buried water supply system in residential area, industrial and water treatment pipeline system.

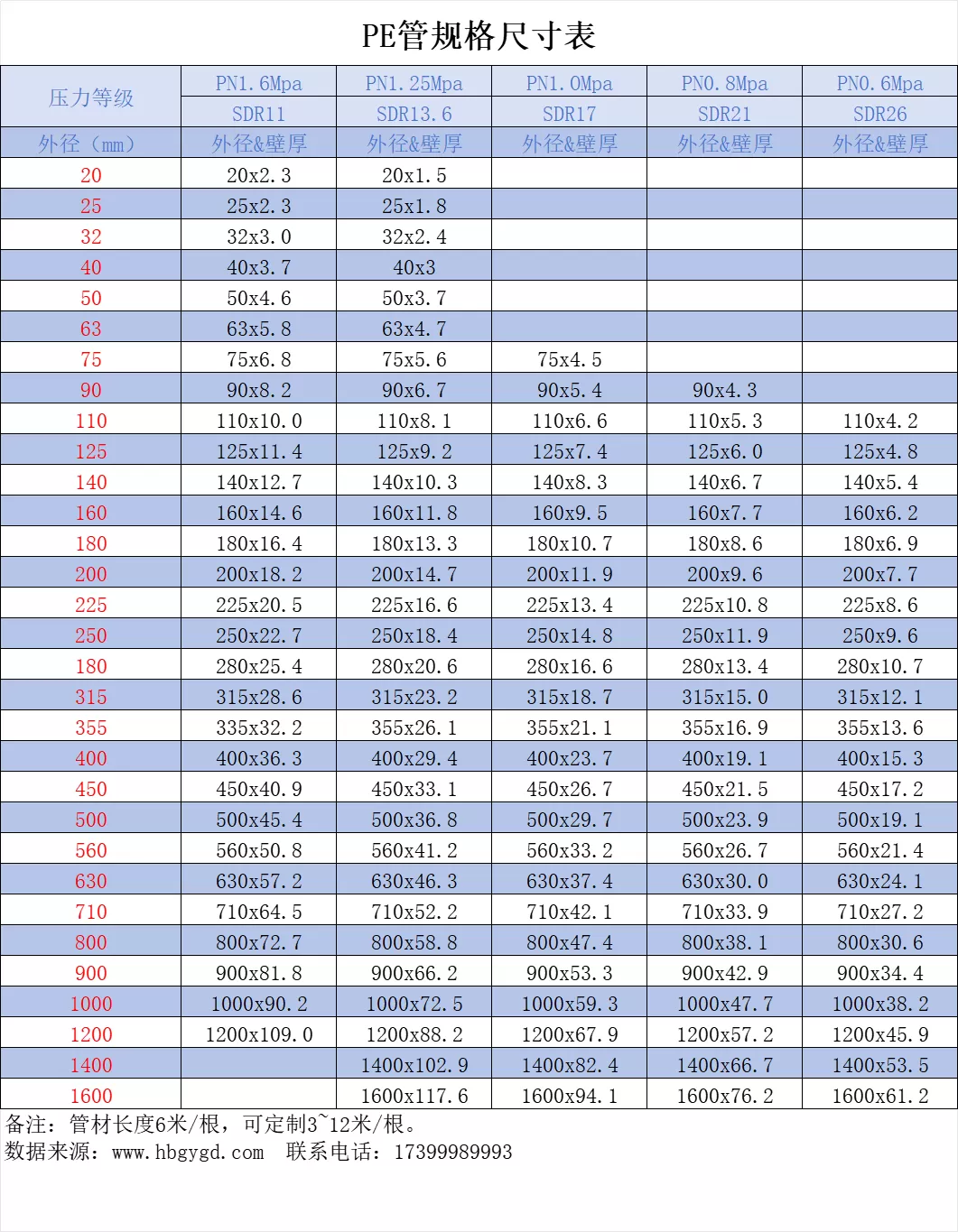

Product specifications:

Pipeline connection:

1. The main connection methods of the pipeline are:

(1) dns63, hot melt socket connection or electrofusion connection;

(2) dn275, hot melt butt or electrofusion connection should be used;

(3) The connection with metal pipes and pipeline accessories can be connected by flange connection or transition pipe fittings.

2. When using this method to connect the hot melt socket, using a hot melt welding machine, the specific steps are as follows:

①, check the surface quality of the pipe, the connection part is clean and non-destructive, and the flat surface of the fracture is smooth and free of burrs.

②, measure the depth of the socket, and mark it on the surface of the pipe.

③, the nozzle is treated with a special scraper on the surface of the pipe connection part to ensure that the periphery is a new surface layer, the mouth should be chamfered, the groove should be 30, the surface groove length is not more than 2.0mm.

④, the pipe fitting socket surface is wiped with a dry cloth to clean the surface.

⑤, insert the pipe and the pipe fitting into the heater without rotation at the same time to heat the connection part.

(6), heated to a predetermined time, pull out the pipe, pipe fittings, quickly and smoothly and uniformly push the pipe into the pipe fitting socket, forming a flange ring around the socket.

0006, pipe, pipe fittings exceed the specified cooling down before the next step.

3. When the hot melt butt

using this method of connection, using hot melt butt welding machine, the specific steps are as follows:

①, prepare the required tools.

②, the pipe to be connected is placed on the welding machine fixture and clamped, clean the pipe to be connected and milling the connecting surface, straighten the two pairs of connectors, so that the amount of dislocation is not greater than 10% of the wall thickness.

③, put into the heating plate to start heating, heating is completed, take out the heating plate, quickly join the two heating surfaces, boost to the welding pressure and pressure cooling.

4. Electrofusion connection

①, clean the dirt on the surface of the pipe to be connected, mark the insertion depth.

②, scrape off the skin.

③, the electrofusion pipe is sleeved on the pipe, and the pipe is straight to ensure that it is on the same axis.

④ Electricity welding, there should be a little melt ejection in the hole to be observed.

⑤ Cooling, electrofusion is completed.