PVC-U water supply pipe product introduction

product introduction

PVC-U water supply pipe, as a mature water supply pipe, has acid resistance, alkali resistance, strong corrosion resistance, good pressure resistance, high strength, light weight, low price, small fluid resistance, no secondary pollution, meets hygiene requirements, convenient construction and operation and other superior performance.

PVC-U water supply pipe pipes and pipe fittings are produced according to the national standards GBT1202.1-2006 and GB/T1202.2-2003. The products comply with the requirements of GB17219-1998 standards and the relevant health and safety evaluation regulations of the Ministry of Health.

PVC-U water supply pipe can replace the traditional water supply pipe, can eliminate secondary pollution, so that people can drink clean, healthy water PVC-U water supply pipe after strict testing shows that the product meets the requirements of various hygiene standards, is a truly healthy, environmentally friendly new product.

Main features

1. Light weight, easy handling and unloading - small density, easy handling, loading and unloading, construction.

2. Excellent corrosion resistance - with excellent acid resistance, alkali resistance, corrosion resistance.

3. Low fluid resistance - the inner wall of the pipe is smooth, its roughness coefficient is only 0.009, the fluid resistance is small, effectively improve the hydraulic conditions of the pipe network, reducing the system operating costs.

4. High mechanical strength - the pipe has good pressure resistance, impact resistance and tensile strength properties.

5. Easy construction - the pipeline connection construction is fast and easy, and the construction project cost is low.

6. Low cost - low price, and convenient transportation, construction, long service life, so the overall cost is low.

7. Does not affect the water quality - confirmed by the dissolution test does not affect the water quality, suitable for large-scale application.

Product application range

1. Indoor water supply and reclaimed water system for civil buildings and industrial buildings.

2. Buried water supply system for residential quarters and factories.

3. Urban water supply pipeline system.

4. Water treatment pipeline system for water treatment plants.

5. Seawater aquaculture.

6. Garden irrigation, well drilling and other projects and other industrial pipes.

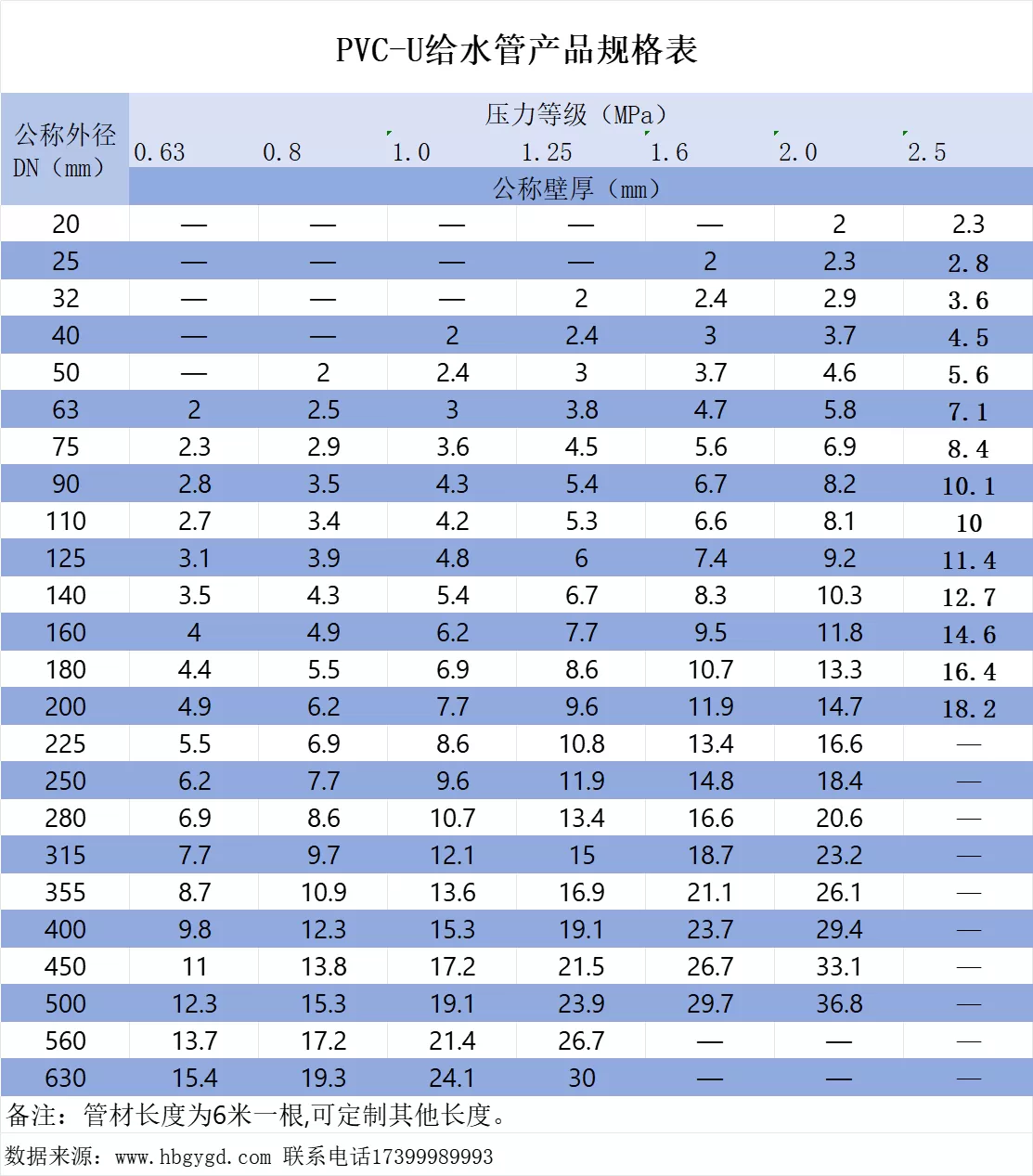

Product Specifications:

bonding steps

1. Choose a fine-toothed saw, cutter or special PVC-U pipe cutting tool to cut the pipe evenly and vertically according to the required size.

2. Remove the burrs and burrs of the fracture with a file, and process the chamfers at the ends. Before applying the adhesive, use a dry cloth to stick the surface debris, dust and water at the socket.

Wipe off the oil stains.

3. Use a brush to apply the special adhesive evenly and quickly on the bonding surface of the socket and socket.

4. Find the center of the pipe and the pipe fitting, quickly insert the socket into the socket and turn it 1/4 turn, so that the adhesive can be evenly distributed and cured

5. Wipe off the excess adhesive on the surface of the pipe with a cloth, and test the pressure with water after connecting for 24 hours.

elastic sealing ring plug-in flexible connection step

1. Clean the outer wall of both ends of the pipe socket Check whether the socket tube has been chamfered.

2. Take out the rubber ring and wipe it clean and then put it in.

Apply lubricant to the insertion part of the inner surface of the socket tube and the end of the socket tube (usually soapy water, cleaning essence).

3. Mark the insertion length mark on the end of the socket tube (leave an appropriate gap between the two tubes for expansion and contraction, the small diameter is about 10mm, and the large diameter is about 25mm).

4. Socket Socket, (small diameter is manually plugged, and the medium and large diameter are plugged with corresponding tools such as wire pliers and gourds).