4, PE pipe acceptance, storage, handling and transportation (AD PE pipe, AD pipe)

1, general provisions① Pipes and fittings should have the product quality inspection report of the quality inspection department and the certificate of conformity of the manufacturer.

② When storing, handling and transporting pipes, non-metallic ropes should be used to bundle, and the end of the pipe should be sealed.

③ When storing, handling and transporting pipes and fittings, they must not be thrown and cracked.

④ When storing, handling and transporting pipes and fittings, they must not be exposed to the sun and rain; they must not be in contact with other chemical substances such as oil, acid and salt.

⑤ Pipes and fittings should not be stored for more than one year from production to use.

2, material acceptance

① Receiving pipes and fittings must be accepted. First accept the product instruction manual, product certificate, quality guarantee and various performance inspection and acceptance reports and other relevant materials.

② When accepting pipes and pipe fittings, samples should be taken in the same batch, and according to the current national standard "Water supply (PE) polyethylene material" for specification size and appearance performance inspection, and comprehensive testing should be carried out when necessary.

3, storage

① Pipes and pipe fittings should be stored in a well-ventilated warehouse or a simple shed with a temperature not exceeding 40 ° C.

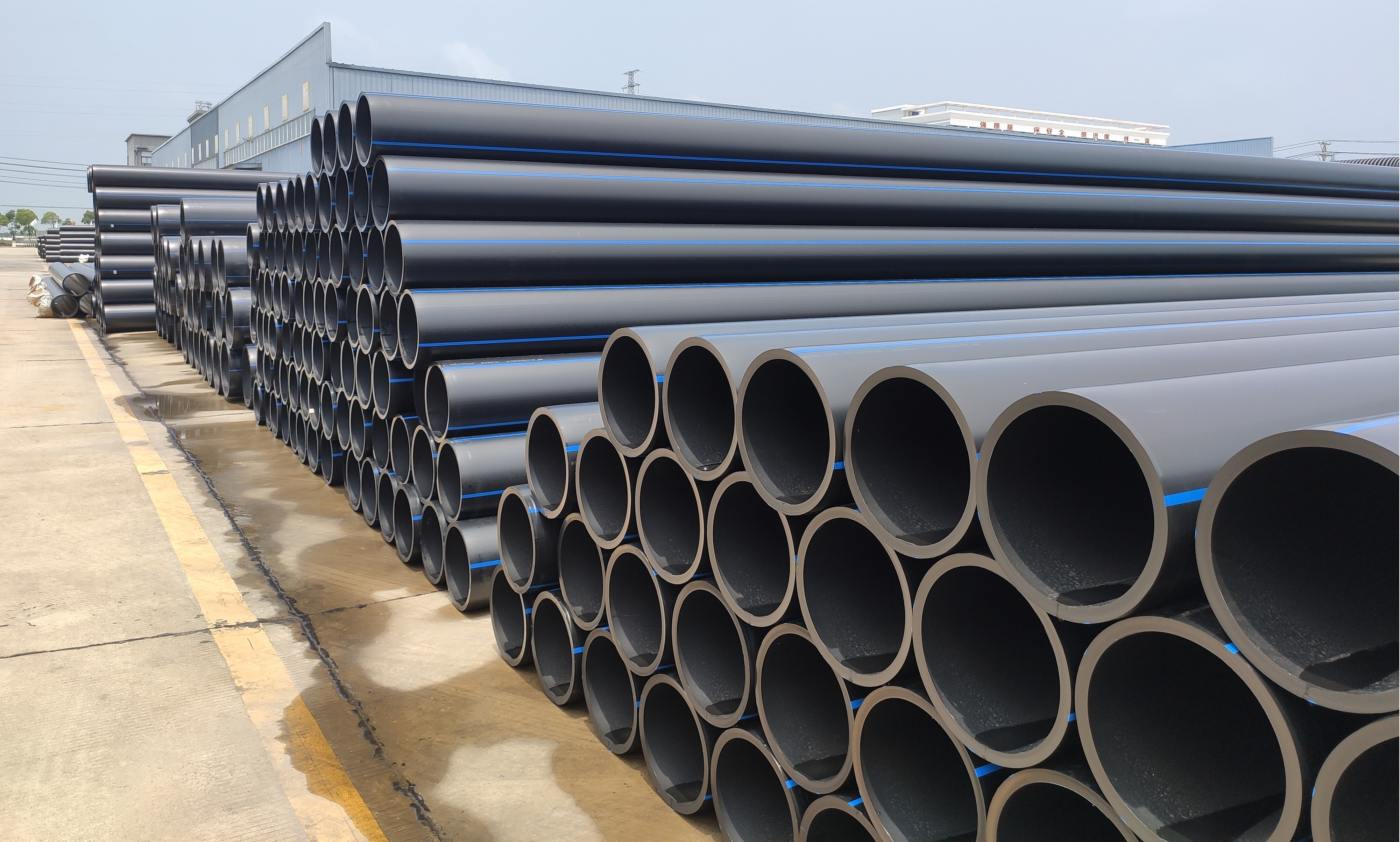

② Pipes should be stacked horizontally on a flat support or on the ground. The height of stacking should not exceed 1.5 meters. When the pipes are bundled into 1m x 1m square bundles and supported on both sides for protection, the stacking height can be appropriately increased, but it should not exceed 3m. The pipe fittings should be stacked neatly layer by layer, and should be ensured not to collapse, and easy to take and manage.

③ When the pipes and pipe fittings are temporarily stacked outdoors, there should be a cover.

④ When the pipes are stored, the pipes of different diameters and different wall thicknesses should be stacked separately.

4, handling

① When the pipes are transported, they must be hoisted with non-metallic ropes.

② When the pipes and pipe fittings are transported, they should be handled with care and arranged neatly. Do not throw and drag along the ground.

③ When handling pipes and pipe fittings in cold weather, severe impact is strictly prohibited.

5, transport

① When the vehicle transports the pipes, it should be placed on the bottom of the flat car, and when shipping, it should be placed in a flat cabin. During transportation, the whole length of the straight pipe should be supported, and the coils should be stacked neatly. Straight pipes and coils should be bundled and fixed to avoid colliding with each other, and stacking should not touch the sharp and convex objects that may damage the pipes.

② When transporting pipe fittings, they should be stacked neatly and fixed firmly in boxes.

③ Pipes and pipe fittings should be covered during transportation to avoid exposure to sun and rain.

5. Material used

ABS (acrylonitrile-butadiene-styrene copolymer)Unplasticized polyvinyl chloride (UPVC)

CPVC (post-chlorinated polyvinyl chloride)

PP (polypropylene)

PE (polyethylene), also known as LDPE, MDPE and HDPE (low, medium, and high density)

6. Connecting technology

has developed to today, the connection technology of polyethylene has been very mature and reliable. Statistics show that the leakage rate of polyethylene pipe is less than 2/100,000, far less than 2-3% of ductile iron pipe, AD pipe PE pipe, which greatly improves the safety and economic benefits of the pipeline, which is also a very important reason for the use of polyethylene pipe more gas pipelines.

Source: Hubei AD Building Materials Co., Ltd., welcome to share! Consultation Hotline: 17399989993